Variables related to other processes with medication use can also affect the actual dose delivered to the patient . Further, nurses who recognize that overfill might be present in a pharmacy-prepared infusion bag or bottle have often misunderstood the "extra" solution as a pharmacy accommodation for the amount of drug lost in the tubing. Thus, the 20 to 25 mL of solution in pump tubing sets, which may account for a significant portion of the total dose, will not be received because the bag would not be completely infused.

Variables related to other processes with medication use can also affect the actual dose delivered to the patient. Thus, the 20–25 mL of solution in pump tubing sets, which may account for a significant portion of the total dose, will not be received because the bag would not be completely infused. A group purchasing organization contracted with a new compounding pharmacy to provide cyclophosphamide and gemcitabine solutions to hospitals. These drugs were used as part of regimens to treat various solid tumor malignancies, lymphoma, and leukemia in adults and children. A discrepancy in labeling on a gemcitabine preparation between the previous supplier and the new supplier led a hospital pharmacist to ask the compounding pharmacy for clarification.

It then became apparent that there was a misunderstanding about how the compounded solutions were being used by the hospitals. The new compounding pharmacy thought that each full bag of gemcitabine and cyclophosphamide contained a single dose to be administered to a single patient. However, the hospitals were using each bag as a multidose product, apportioning the medication from a single bag among several patients. Believing each bag was a single dose, the compounding pharmacy did not account for the volume of overfill in the bag when labeling the concentration of the prepared product. Although the full dose in each bag was listed on the label, the actual concentration of the drug in each bag was lower than stated due to overfill in the normal saline bags used to dilute the medication.

How To Calculate Maximum Volume Chemistry The best estimate is that the average actual cyclophosphamide concentration was 10% lower than stated on the label, and the average actual gemcitabine concentration was 7% lower than stated on the label. A group purchasing organization had recently contracted with a new compounding pharmacy to provide cyclophosphamide and gemcitabine solutions to hospitals. These drugs were used as part of regimens to treat various solid tumor malignancies, lymphoma, and leukemia in both adults and children. The new compounding pharmacy thought each full bag of gemcitabine and cyclophosphamide contained a single dose to be administered to a single patient.

While the full dose in each bag was listed on the label, the actual concentration of the drug in each bag was lower than stated due to overfill in the normal saline bags used to dilute the medication. Prepared medications intended for multiple doses. The preparation of medications for multiple doses (e.g., bulk preparation) ideally requires full sterile compounding of the product. Bags containing the manufacturer's base solution contain a variable amount of overfill, and specific concentrations of drugs can be prepared only by starting with an empty bag or other container. Keep in mind that an error occurring early in the process (e.g., during medication reconstitution) may have an impact on the dose of medication received by multiple patients.

Therefore, pharmacies that prepare IV medications intended for multiple doses should proactively evaluate their processes and take necessary precautions to mitigate identified risks. Thus, the mL of solution in pump tubing sets, which may account for a significant portion of the total dose, will not be received because the bag would not be completely infused. The prescribed medication is added to a manufacturer's base solution container, such as 0.9% sodium chloride, in an intravenous bag without concern for overfill. This is typically used for the admixture of intermittently administered solutions when the entire bag is intended to be infused to a single patient over a short time .

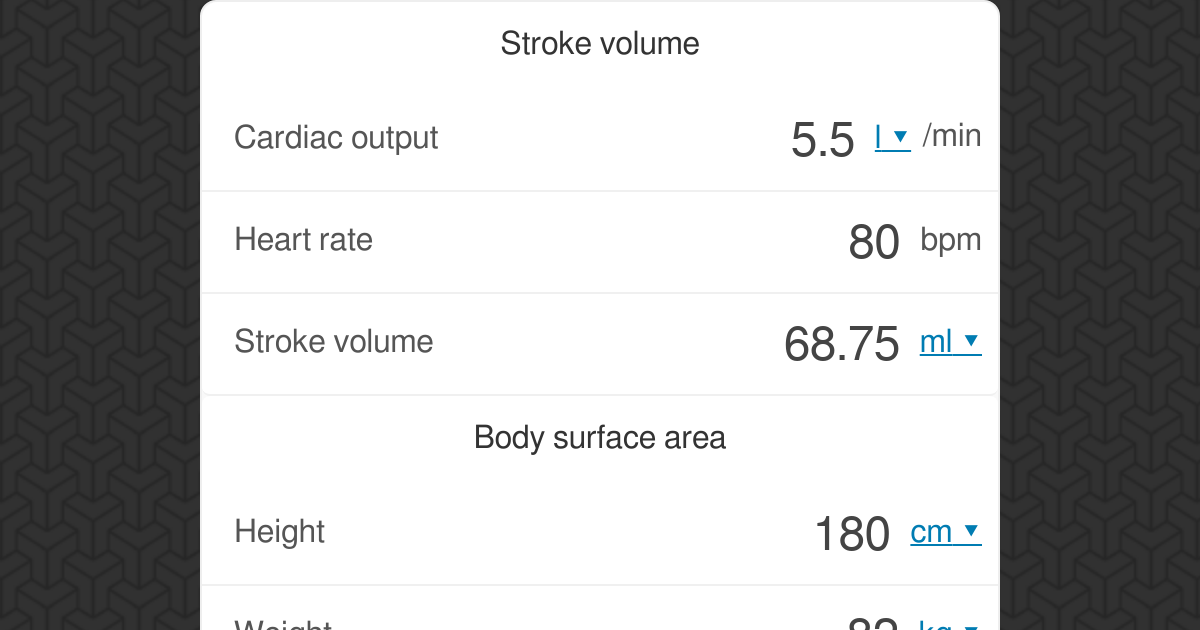

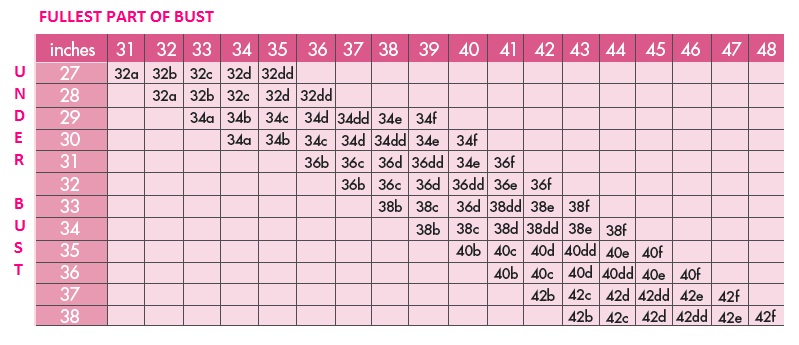

This method may also be used to prepare medications administered via continuous infusion when the slight difference in per mL concentration may not be as important because the effect of the medication is being continuously monitored . This is typically used for the admixture of intermittently administered solutions when the entire bag is intended to be infused to a single patient over a short time (e.g., 30 minutes). The prescribed medication is added to a manufacturer's base solution container, such as 0.9% sodium chloride, in an IV bag without concern for overfill. The 10% rule is used by some hospitals during the preparation of infusions to determine whether fluid should be removed from the bulk solution container prior to the addition of the medication. The rule suggests that if the volume of the additive medication is more than 10% of the volume listed on the bulk solution container , the volume of the additive, and sometimes the volume of the overfill, will be removed.

Unless starting with an empty bag , the 10% rule is often applied to all admixtures, except small volume intermittent solutions such as antibiotics or other products with manufacturer-specified preparation procedures. Whatever method is chosen, it is critical to be consistent within your organization. During preparation of infusions, the 10% rule is used by some hospitals to determine whether fluid should be removed from the bulk solution container prior to the addition of the medication. Unless starting with an empty bag , the 10% rule is often applied to all admixtures except small-volume intermittent solutions such as antibiotics or other products with manufacturer-specified preparation procedures. Unless starting with an empty bag , the 10% rule is often applied to all admixtures except small volume intermittent solutions such as antibiotics or other products with manufacturer-specified preparation procedures.

In practice, there are several different practitioner- and manufacturer-based preparation methods. The preparation method used affects the total volume and concentration of the final product. In practice, there are several different practitioner-based and manufacturer-based preparation methods.

Health care organizations must develop standardized preparation methods that are appropriate for various clinical situations. When doing this, it is important to balance the benefits of process changes against additional risks that such changes may present. In particular, changes that increase the manipulation of products or the complexity of processes can pose new risks that outweigh the benefit of added dosing accuracy. There is no single, standard method appropriate for all infusions in all hospitals, particularly given the variability in environmental conditions, staff expertise, and technology among hospitals. However, consider the following points when designing processes in your hospital for admixture and sterile compounding.

Health care organizations must develop standardized preparation methods appropriate for various clinical situations. Healthcare organizations must develop standardized preparation methods appropriate for various clinical situations. The final container should not be labeled with a specific concentration per mL because of the unknowns. The pharmacist may or may not add more drug to offset the overfill volume.

These bags should only be labeled with the total amount of drug in the container and the total estimated volume. Only with method 4 can the concentration be accurately calculated and added to the pharmacy label. A volume of the base solution equal to the sum of the volume of the medication to be added to the container and the estimated volume of overfill is withdrawn from the manufacturer's container.

The medication is then added to the remaining volume in the container. This method is typically used when the volume of medication to be added is large relative to the size of the base solution container. A volume of the base solution equal to the volume of the medication to be added to the container is withdrawn from the manufacturer's container, without concern about overfill. For example, before adding 150 mL of sodium bicarbonate from a syringe or vial to a 1,000 mL bag of dextrose 5%, a volume of 150 mL of the base solution is withdrawn from the bag and discarded.

For example, before adding 150 mL of sodium bicarbonate from a syringe or vial to a 1,000-mL bag of dextrose 5%, a volume of 150 mL of the base solution is withdrawn from the bag and discarded. The estimated volume of overfill is withdrawn from the manufacturer's container. For infusions in which the dose remaining in the tubing must also be infused to deliver the entire dose , the product label should specify that the tubing should be flushed with a particular diluent and volume. When the rate of administration is critical, as for some IV medications given intermittently by infusion pump, ensure that information about the rate of administration and flush is built into relevant protocols and smart infusion pumps.

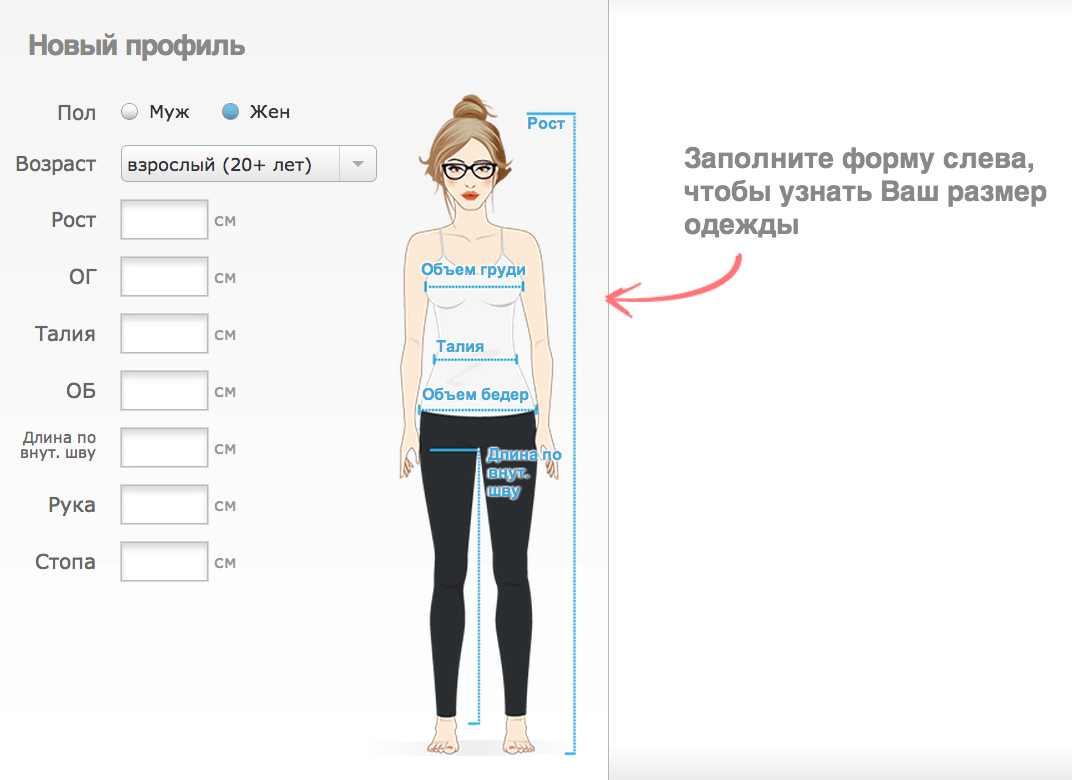

In general, the preparation of a compounded medication infusion involves diluting the drug with a diluent and transferring the prescribed amount of drug into a final dosage container . Although a commercially available bag or bottle of parenteral solution may be labeled to contain 25, 50, 100, 250, 500, or 1,000 mL, the actual volume is larger because it contains overfill. The containers may be permeable to oxygen and experience a loss of water to some extent, depending on the storage conditions, specific contents, permeability of the container, and ratio of fluid volume to the container surface area. Thus, there is some variability in the targeted amount of overfill specified by each manufacturer in each bag, as well as variability in the contents of any bag at any point in time.

Despite this variability, vendors of solutions can provide customers with a targeted amount and range of overfill in each of their products. Choose the most appropriate method of preparing each medication infusion according to whether or not the volume is critical. Start by developing a list to identify medications and situations for which added accuracy in dose or concentration is needed and the level of accuracy required. This list will help determine which preparation method should be used for specific drugs. Also, obtain a list of overfill amounts of commonly used products from vendors for reference as necessary.

"The new compounding pharmacy thought each full bag of gemcitabine and cyclophosphamide contained a single dose to be administered to a single patient. However, the hospitals were using each bag as a multidose product, apportioning the medication from a single bag among several patients," ISMP wrote in its November 14, 2013, Medication Safety Alert newsletter. A medication for parenteral use is manufactured in large quantities to a specific concentration (eg, mg/mL). The required volume of this solution, in addition to the overfill containing the medication at the same concentration, is added to an empty parenteral container. This method is used for commonly manufactured premixed solutions approved by the US Food and Drug Administration .

With this method, the medication concentration in the container at the time of manufacture is the same as the concentration on the label. However, the final product contains more volume than the label indicates due to overfill. For example, an IV bag of gentamicin labeled as containing 80 mg/100 mL contains the labeled 80 mg and another 4 mg of the drug in the 5 mL of overfill. As a result, hospitals need to develop standardized preparation methods.

"There is no single, standard method appropriate for all infusions in all hospitals, particularly given the variability in environmental conditions, staff expertise, and technology among hospitals," ISMP wrote. In some cases, hospital staff have difficulty determining chemotherapy dosing because of the variability in overfill. Although bags or bottles of parenteral solution may be labeled to contain 25,50, 100, 250, 500, or 1,000 mL, the actual volume is larger because it contains overfill. In addition, there was a misunderstanding between the pharmacy and the hospital. A group purchasing organization had contracted with a new compounding pharmacy to provide cyclophosphamide and gemcitabine solutions to hospitals. A discrepancy in labeling between the previous supplier and the new supplier on a gemcitabine preparation led a hospital pharmacist to ask the compounding pharmacy for clarification.

The measured amount of medication and base solution are added to an empty IV bag or other container. With this method, there is no overfill. This method may be used when both the total amount of drug in the final container and the concentration of drug need to be precise and must be accurately known. The final container can be labeled with a specific drug concentration (mg/mL). Both the measured amount of medication and base solution are added to an empty IV bag or other container. A supplier (e.g., compounding pharmacy) may use any of the practitioner-based methods or the manufacturer-based method described above to prepare individual doses of IV medications.

Medications administered by continuous IV infusion are typically titrated to a desired effect . Thus, the key strategy with these infusions is to ensure consistency in the preparation process in order to avoid variations in concentration and inconsistencies with the dose delivered. In these instances, a standard process for simple admixture may be all that is needed to ensure consistency from bag to bag and the desired therapeutic effect. Medications administered by continuous IV infusion are typically titrated to a desired effect (e.g., pain relief with opioids, blood pressure control with vasopressors, anticoagulation with heparin). In this program, you will gain knowledge on safe practices for preparing and checking pharmaceutical calculations in both sterile and non-sterile compounds. Additionally, you will review some practical examples such as overfill volume, total parenteral nutrition and prednisone taper.

A medication for parenteral use is manufactured in large quantities to a specific concentration (e.g., mg/mL). This method is used for commonly manufactured premixed solutions approved by the Food and Drug Administration. Knowing how to properly complete pharmaceutical calculations is important for pharmacists and pharmacy technicians, as it is required to perform and check several calculations daily.

In August, ISMP Canada reported that more than 1,100 patients in Canada received diluted, or less potent chemotherapy doses. Larger bags of chemotherapy had been used to prepare smaller, individual doses of chemotherapy, but the overfill bags used to prepare and administer the chemotherapy were not managed correctly, according to the ISMP. A supplier may use any of the practitioner-based methods or the manufacturer-based method described above to prepare individual doses of IV medications.

Every day, millions of patients and caregivers rely on Baxter's leading portfolio of critical, nutritional, renal, hospital and surgical care products and services. For more than 85 years, we've been operating at the critical intersection where innovations that save and sustain lives meet the healthcare providers that make it happen. Table 1highlights a few of these sources of variability. Improper dosing of chemotherapy in IV bags recently caused a problem among a group of patients in Canada, so the Institute for Safe Medication Practices is cautioning healthcare practitioners about chemotherapy dosing.

Abacus Software offers you the ability to create multiple customized order templates, including Premix ones, that support your prescribing practices and facilitate multiple referral sources. Your Abacus Software administrator can apply your facility's therapeutic and pharmacy practice rules to your software, and it also allows for the addition of Premix parenteral nutrition to the Formulary. Miscalculations can be a common cause of medication errors.

It is important as a pharmacy professional to be thorough and precise while performing or checking all pharmaceutical calculations. Different administration practices (eg, medication remaining in IV tubing; pump alarm stoppages). Caring for hospitalized patients is complex. That's why Baxter is focused on partnering with healthcare systems to enable clinicians to provide their best care to patients. This professional development program is developed for pharmacists and pharmacy technicians who would like a review of common pharmaceutical calculations in practice.

Ensure the patient is educated about and understands how to properly use the medication and device. Regulations allow variances in the volume infused by infusion pumps. These medication errors have occurred in health care facilities at least once. They will happen again—perhaps where you work. Through education and alertness of personnel and procedural safeguards, they can be avoided.

You should consider publishing accounts of errors in your newsletters and/or presenting them at your inservice training programs. Abacus Software performs daily automatic archiving and offers reporting tools to help support pharmacy tracking and decision making. Use the software to automatically calculate ion and salt-based ingredient volumes needed.

It also compares the original patient order with subsequent orders to indicate variances. Labels contain unique barcodes, prescription numbers, serial numbers and order information. The practices, processes, and equipment used to determine a dose in a clinical trial may differ from the practices, processes, and equipment used in a particular environment. ISMP Canada Managing overfill during preparation and delivery of intravenous medications. The prescribed date and time for administration are printed clearly on the label of each numbered bag, along with the nutritional summary and formula. Only users with appropriate permissions can approve an order.

Discover how to avoid calculation errors through practical examples and review commonly encountered pharmaceutical calculations. Regulations allow variances in manufactured doses of medications. Abacus software give clinicians, pharmacists and technicians access to verify and edit patient information from the order screen. Manufacturers of base IV bag solutions will often ________ each bag to accommodate for the fact that the IV may be stored for long periods in uncontrolled conditions.